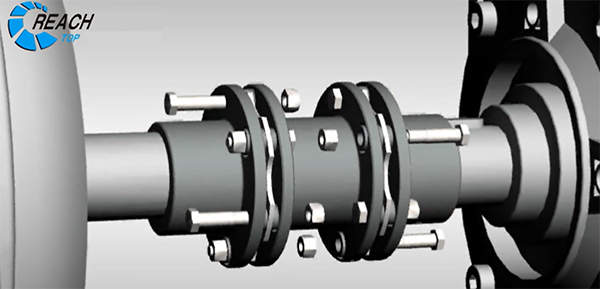

ISAHaɗin kai tsakanin diaphragmna'urar watsawa ce da aka saba amfani da ita, inganci da basirar taronta suna da tasiri mai mahimmanci akan aikinta na yau da kullun da rayuwarta.Daga cikin su, hanyar haɗuwa da yanayin zafi yana ɗaya daga cikin ƙwarewar haɗuwa da aka saba amfani da su.

Hanyar haɗuwa da yanayin zafi yana haifar dahadaddun diaphragmko magudanar da za a yi faɗaɗa zafin zafi ko ƙanƙantar sanyi ta hanyar dumama ko sanyaya, ta yadda za a sauƙaƙe haɗa ƙafafun da ke haɗa ƙafar zuwa ramin.Idan aka kwatanta da a tsaye hanyar shigar da latsawa da kuma hanyar latsawa mai ƙarfi, hanyar haɗuwa da yanayin zafi yana da fa'idodi da yawa kuma ya dace musamman ga cibiyoyi da aka yi da kayan gaggautsa.Gabaɗaya, ana amfani da dumama don haɗuwa da bambancin zafin jiki, kuma ba a cika yin amfani da sanyaya ba.Akwai hanyoyin dumama da yawa;na kowa shine dumama wankan mai da toyawa.Matsakaicin zafin jiki na wanka mai mai ya dogara da yanayin mai, gabaɗaya ƙasa da 200 ° C.Lokacin amfani da wasu hanyoyin dumama, zafin jiki na haɗin gwiwa zai iya wuce 200 ° C, amma la'akari da tasirin metallography da maganin zafi, zafin zafin jiki na haɗin diski bai kamata ya wuce 430 ° C ba, in ba haka ba zai haifar da canje-canje a cikin tsarin ciki. na karfe.Sabili da haka, don dalilai na aminci, babban iyakar zafin jiki na dumama ya kamata ya kasance ƙasa da 400 ° C.Don Isarwadiaphragm couplings, Za'a iya ƙididdige ainihin zafin jiki na dumama da ake buƙata bisa ga ƙimar tsangwama tsakanin haɗawa da shaft da buƙatun yayin haɗuwa.Hanyar haɗuwa da bambancin zafin jiki shine fasaha da aka saba amfani dashi a cikin tarondiaphragm couplings.Ƙwarewa mai ma'ana da kuma amfani da wannan hanya na iya inganta haɓaka da ingancin taro yadda ya kamata.

Abin da ke sama shine gabatarwar hanyar haɗuwa da bambancin zafin jiki, ɗaya daga cikin ƙwarewar haɗuwa na REACH diaphragm coupling ko disc coupling, da fatan zai zama taimako a gare ku!

Tuntube mu asales@reachmachinery.comdon samun ƙarin shawarwarin taro daga gare mu!

Lokacin aikawa: Juni-26-2023