contact: sales@reachmachinery.com

Electromagnetic brakes are widely used in various industrial applications to control the speed and motion of rotating machinery. Choosing the right electromagnetic brake is crucial to ensure efficient and safe operations. What’s the key factors when selecting an electromagnetic brake for a specific application.

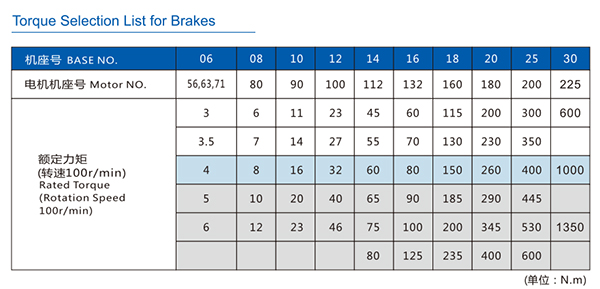

Torque Requirements:

Identify the required braking torque for the application. Consider the maximum load, operating conditions, and safety margins. Ensure the selected electromagnetic brake can provide adequate torque to handle the load and bring it to a controlled stop.

Voltage and Power Supply:

Check the voltage and power supply compatibility of the electromagnetic brake with the existing system. Verify whether the available power source can deliver the required voltage and current for optimal brake performance.

Operating Environment:

Assess the operating environment of the brake system. Consider factors such as temperature, humidity, dust, and exposure to chemicals or corrosive substances. Choose an electromagnetic brake with appropriate sealing and protection to withstand harsh conditions.

Response Time:

Evaluate the required response time for the brake to engage and disengage. In some applications, quick response times are critical for safety or precise control. Select a brake that can meet the desired response time without compromising performance.

Size and Mounting:

Consider the available space and mounting requirements in the application. Choose an electromagnetic brake that fits within the allocated space and can be easily mounted without extensive modifications to the machinery.

Life Cycle and Maintenance:

Assess the expected life cycle of the electromagnetic brake under the given operating conditions. Consider factors such as wear and tear, maintenance requirements, and the availability of replacement parts. Opt for a brake with a long service life and straightforward maintenance procedures.

Noise and Vibration:

Evaluate the noise and vibration levels produced by the electromagnetic brake during operation. In noise-sensitive environments or precision applications, select a brake with low noise and vibration characteristics to prevent disturbances and ensure smooth operations.

Control and Integration:

Consider the control mechanism required to engage and disengage the brake. Determine whether the brake can be easily integrated into the existing control system or if additional components are needed for seamless operation.

Cost-effectiveness:

Compare the cost of the electromagnetic brake with its performance and features. Avoid over-specifying the brake if the application does not demand it, and aim for a cost-effective solution without compromising on safety and functionality.

Conclusion:

Selecting the right electromagnetic brake involves a careful evaluation of torque requirements, power supply compatibility, operating environment, response time, size, life cycle, noise and vibration levels, control integration, and cost-effectiveness. By considering these key factors, one can ensure the optimal performance and safety of the brake system in the intended application.

Post time: Aug-01-2023