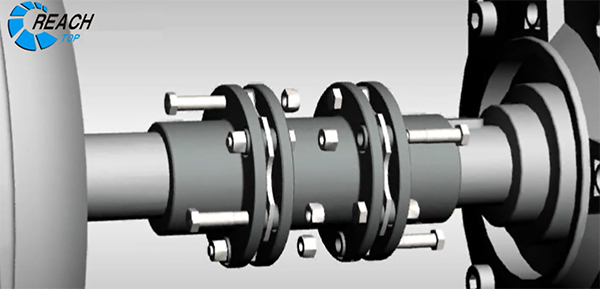

In the assembly process of a REACH membrane coupling or disc coupling or diaphragm coupling, the power press-in method is a commonly used technique that is suitable for cases where the fit is transitional or the interference is not significant. However, this method also carries certain risks and has specific applications depending on the material. Next, we will introduce details:

The power press-in method refers to the use of impact tools or mechanical force to complete the assembly of the Reach rigid membrane coupling. Generally, this assembly method is suitable for cases where the fit is transitional or the interference is not significant. In the assembly site, the common practice is to use a hammer to strike. The specific method is to place a wooden block or other soft material as a cushion on the hub face and rely on the impact force of the hammer to install the Reach coupling onto the shaft.

In summary, the power press-in method is a commonly used approach in the assembly of REACH rigid membrane couplings or disc couplings. It can efficiently complete the assembly task while meeting specific requirements. Whether in large-scale projects or daily maintenance, a proper understanding and application of the power press-in method is essential in ensuring the installation quality and service life of couplings. Therefore, for industries or individuals that frequently require coupling assembly, mastering and applying the power press-in method is an indispensable skill.

Post time: Jul-28-2023