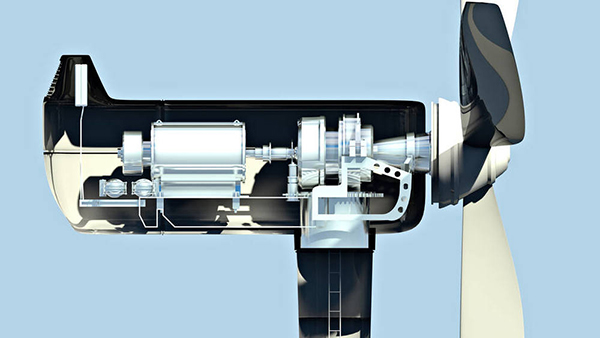

In the world of wind energy, every component plays a key role in ensuring the efficient operation of a turbine. One such important component is the shrink disc, which is widely used in the gearboxes and yaw drives of wind turbines.

Wind energy is becoming an increasingly popular source of renewable energy. As the size and power output of wind turbines continues to grow, it is more important than ever to ensure that all components work together efficiently and safely. One of these components, the shrink disc, plays a critical role in connecting the key components of the turbine, including the gearbox and generator.

Shrink Disc from REACH MACHINERY

The Shrink disc works by using friction to create a tight connection between two components. Choosing the correct type and size of shrink disc can improve the reliability, efficiency, and safety of a wind turbine.

Wind turbines operate in harsh environments and are often subject to wind, rain, and temperature changes. Shrink discs provide reliable and secure connections that can withstand these conditions. Provides a reliable and efficient way to transfer torque between components. When assembled, the shrink disc creates a tight fit between the inner and outer rings, creating friction that prevents slippage or loosening while transmitting power. By converting axial forces into radial forces, these assemblies allow secure connections between rotating elements, thus ensuring optimal performance and service life in harsh wind turbine environments.

As a leading manufacturer of shrink discs, REACH MACHINERY has a dedicated research and design team and several patented designs for REACH series shrink disc, demonstrating its technological prowess in the field of power transmission. With many years of experience serving well-known customers in various industries, REACH has accumulated extensive knowledge of different operating conditions and requirements, making it a reliable partner for wind energy applications. REACH‘s use of high-quality locking components can help minimize downtime and maintenance costs while increasing the energy output and overall efficiency of wind energy applications. The ability to increase reliability and durability to reduce vibration and noise, improve safety, reduce maintenance costs and extend the life of wind turbine components.

Post time: Jun-16-2023