Contact: sales@reachmachinery.com

Shin kun san yadda ake girka ko wargaza majalissar kullewa?Anan akwai jagororin ƙwararrun daga Injin Kai.

Shigarwa

- Da farko, Bincika cewa saman haɗin gwiwa ba shi da lalacewa, lalata, da gurɓatawa.

- Aiwatar da man mai mai mai a saman haɗin gwiwa (shaft da cibiya).(Lura ta musamman: man mai da ake amfani da shi ba dole ba ne ya ƙunshi abubuwa irin su molybdenum disulfide waɗanda ke rage girman juzu'i.) (MoS_2).

- Saka a hankaliMakulle Majalisacikin matsayi mai haɗawa, mai da hankali don hana sha'awar.sannan ku matsa kullin tare da odar giciye na diagonal da hannu.

- Saita karfin juyi zuwa 1/3 Ts, ƙara maƙarƙashiya tare da diagonal a kan tsari daidai.

- Saita karfin juyi zuwa 1/2 Ts, ƙara maƙarƙashiya tare da diagonal a kan tsari daidai.

- Saita juzu'i mai ƙarfi zuwa ƙimar juzu'in da ke sama da Ts 5%, ƙara matsar da kullin tare da diagonal a kan tsari daidai-wai, sa'an nan kuma ƙara duk kusoshi ta hanyar kewayawa.

- Saita spanner mai ƙarfi zuwa Ts;duba idan duk za a iya ƙara sukurori sama.Idan ba a ɗaure wani kusoshi ba, da fatan za a maimaita mataki na 6 da 8. IdanMakulle Majalisaana amfani da shi a cikin waje ko muhalli mai lalata, da fatan za a kula da yin amfani da man shafawa na hana tsatsa akai-akai a samanMakulle Majalisada kusoshi.

Abubuwan da aka kama daga Injin Kai

Watsewa

1. Da farko bincika idan an cire duk kayan aikin watsawa gabaɗaya.

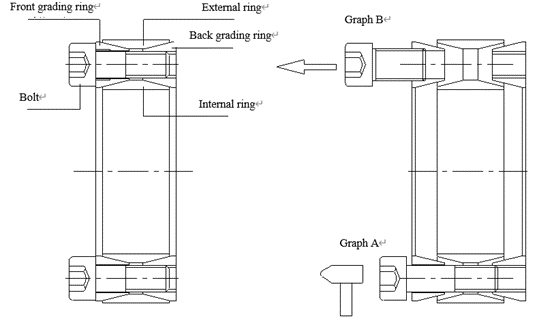

2. Sake duk makullin kulle akanMakulle Majalisa(babu bukatar cire dunƙule gaba ɗaya).A wannan lokacin, zobe na ciki da na waje da zoben matsa lamba naMakulle Majalisazai sassauta ta atomatik.Idan akwai rashin daidaituwa kuma ba za'a iya sassauta shi akai-akai ba, ƙwanƙwasa a hankali kamar yadda aka nuna a cikin zane (duba zane A).

3. Da fatan za a cire fararen kusoshi kuma ku dunƙule babban abin rufe fuska a cikin ramin zaren zoben matsa lamba na gaba, a wannan yanayin,Makulle Majalisaana iya cire shi cikin nasara (duba zane na B).

Lokacin aikawa: Mayu-22-2023