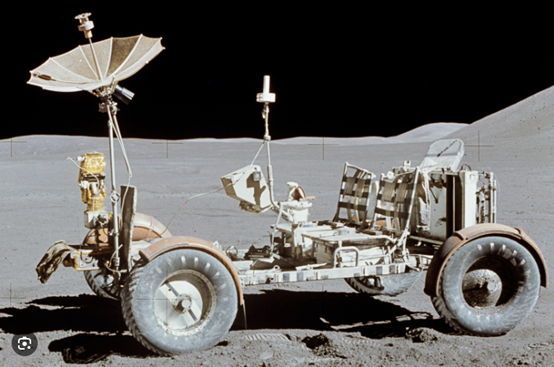

The Apollo 15 rover landed on the moon on July 30, 1971.

On the surface of the moon with a complex environment, the lunar rover needs to be as light-loaded and compact as possible. The bulky and low-ratio gear reducers used on fuel vehicles are obviously difficult to meet their requirements.

Therefore, the harmonic reducer with small mass, high transmission efficiency and high precision began to be valued by NASA, and was finally successfully applied to the Apollo lunar rover in 1971.

The 210KG lunar rover is completely driven by electricity, with four independently driven motors installed, and four sets of harmonic reducers are used to control the motor speed.

In a metal ring with internal teeth, put a flexible ring with the same tooth pitch but fewer teeth, and put an elliptical wave generator with a flexible rolling bearing inside the ring. These three parts are composed a harmonic reducer.

When the motor drives the wave generator to rotate, it will cause elastic deformation of the flexible gear on the outer ring, which also follows the rotation in an elliptical shape. Then the long axis of the flexible wheel is squeezed and inserted into the tooth groove of the rigid wheel of the outer ring to become a fully meshed state.

The meshing process of these two gear rings is actually a flexible gear ring with a small number of teeth rolling on a rigid gear ring with a large number of teeth. Because the teeth in front of the meshing point of the flexible gear are gradually dislocated forward relative to the rigid tooth grooves of the outer ring, the flexible gear teeth are pushed back by the tooth grooves during the meshing process.

In conclusion, the successful integration of the harmonic reducer into the Apollo lunar rover in 1971 marked a pivotal moment in the history of space exploration. This lightweight, compact, and efficient drive train enables the rover to traverse the lunar surface with precision and reliability. The innovative design and application of the harmonic reducer not only contributed to the success of the Apollo 15 mission, but is also one of the core components of the robot.

You can get more information from Reach machinery: sales@reachmachinery.com

Post time: May-31-2023